Challenges in the Smart Monitoring of Aggregates

Critical aggregates (system composed by several separate machines) are equipments for which every unplanned downtime causes significant non-production costs. To avoid them, many critical aggregates are today covered by aggressive and costly preventive maintenance plans.

Predictive maintenance is not very widespread because the costs of digitisation are often high. IoT solutions on the market do not cover the monitoring requirements properly, so that they should be monitored with costly cabled Condition Monitoring Systems (CMS).

Data provided by CMS Systems are complex to analyse and requires special skills.

CMS Systems based on classic vibration monitoring are well known since many years for their ability to detect issues on the shaft dynamic and bearings. But they are quite limited to detection other issues e.g on the inverters or on the mechanical seals.

GradeSens Smart Monitoring Solution

GradeSens offers a cost effective Smart Monitoring Solution for critical aggregates ensuring equivalent or better performance as CMS. Our Solution opens consequently new doors to Smart Maintenance for many aggregates.

Data collected by LYRA is

structured so that it can processed by Analytics effectively. Our Analytics is configured for each type of aggregates toprovide KPIs representative to their main failure modes.

For aggregates with variable loads and speeds, our Analytics combines vibration data with existing process parameters (e.g. provided by the inverter) to build a digital twin with Machine Learning. The digital twin allows you to detect anomalies when condition data (e.g. vibration, temperature) lies outside its operating dependant expected range.

Our Analytics allows to extract features from raw data to detect specific failure modes on the rotor dynamic and bearings using our extended library of algorithmes that is continuously being updated upon our new projets.

Typical applications

Process Equip-ment with variable loads and speed

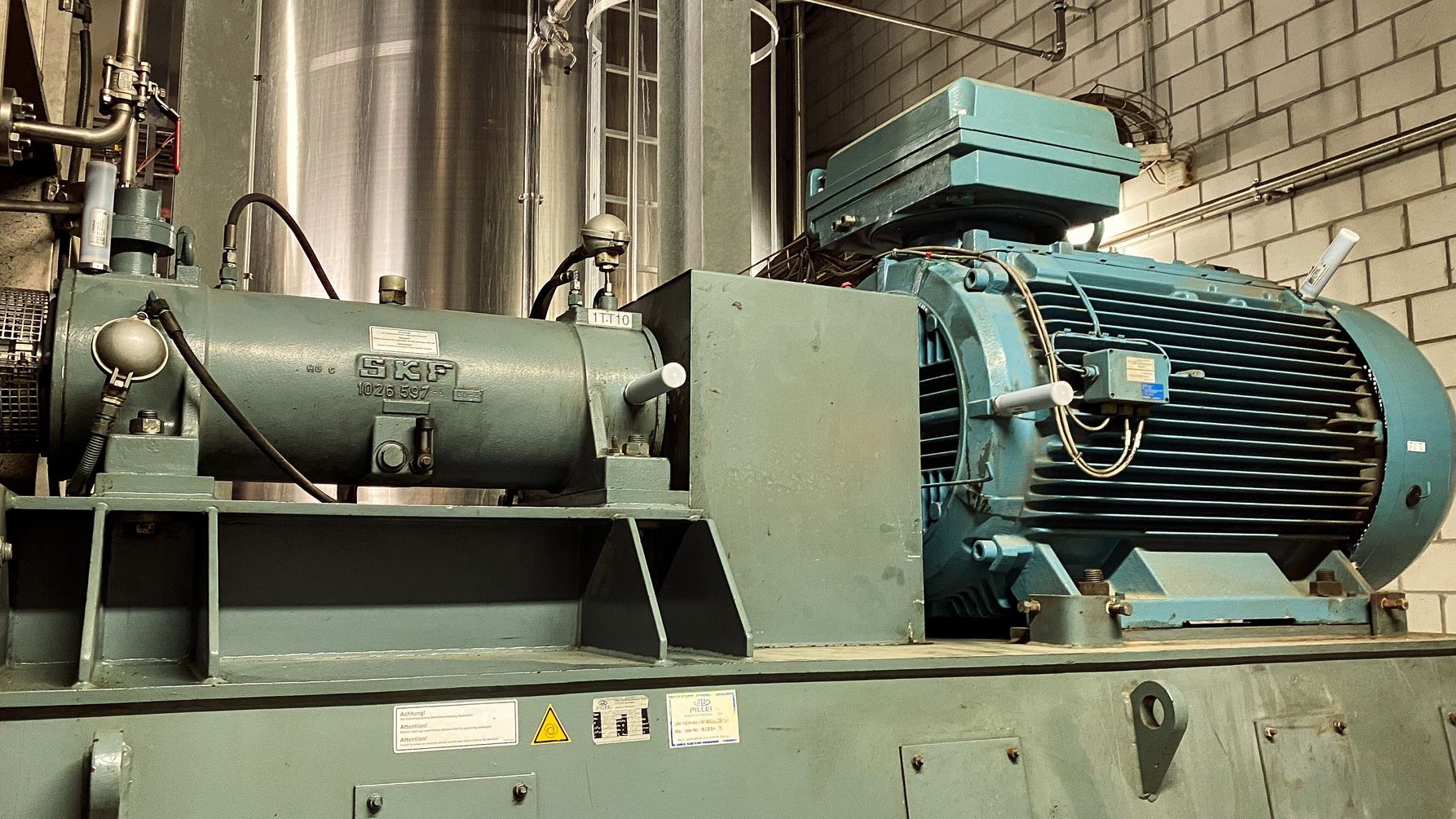

Process Equipments are aggregates consisting of motors, mechanical couplings and process equipments such as pumps, evaporators, compressors or ventilators. To monitor such aggregates effectively, we recommend to install one sensor per bearing and to collect the process data generated by the inverter when the equipment is operated under variable loads and speeds.

For such equipment, GradeSens solution allows to collect vibration and process data in a structured manner so that it can be processed by machine learning to build a digital twin of it behaviour. Anomalies on the rotor dynamic, mechanical sealing, motor, inverter or on the process can be proactively detected to allow the planning of adequate preventive measures during the next scheduled maintenance.

Our solution allows you to get a better insight about the operating condition of your aggregates as a whole, to avoid unplanned shutdown and to focus your scheduled maintenance on what really matter.

Distribution Pumps Systems

Distribution pumps systems consist of several pumps operating in parallel to ensure fluid supplies inside production plants. Generally, the pumps are well recognised for their reliability and are often redundant so that the implementation of predictive maintenance solutions are not necessarily required.

Nevertheless, there are some cases where predictive maintenance makes totally sense, typically, when the hydraulic circuit is subject to water hammers that are strong enough to cause damages on the pumps or when the fluid is sensitive (typically in pharma).

For such a situation, GradeSens recommends installing one sensor per pump and monitoring all pumps synchronously, ideally in combination with process data. This approach allows you to have a global view of your distribution system (not just at the pump level), so that anomalies in the hydraulic circuit can be detected. The proactive detection of these anomalies allows you to take the necessary measures to improve your hydraulic circuit in order to increase the lifetime of its different components (valves, pumps, heat exchangers,...).

Power Generators

Power generators are typically Hydro Turbine Generators (HTG) or Wind Turbine Generators (WTG) used to produce electricity using renewable energy.

With the emerging risks of power shortages, these equipments are getting increasingly vital to ensure the balance of the electricity network.

Today, many WTG and small HTG (<20MW) are not monitored with vibration sensors. The market available solutions are costly and their installation requires from one up to several days of shutdown. WTG are generally designed for 15 to 20 years of operation so that the reliably of power production is ensured by design. The new power market paradigm push the operators and owners to expand the life time of their assets so that the business case for predictive maintenance solutions are getting attractive.

GradeSens allows you implementing a cost effective Condition Monitoring System for your HTG and WTG. Our battery powered sensors LYRASens are almost insensitive to EMC noises so that the highest measurement quality is guaranteed. Our open architecture allows you to get access to sensors data via APIs so that it can be further processed and visualised by 3rd party systems.

Slow Rotating Machines

The vibration measurement of Slow Rotating Machines is an on-going topics for many sensors suppliers. The piezoelectric sensors are not very well suitable for the measurement of vibration below 3Hz. In such cases, the installation of electrodynamic sensors is recommended. These sensors are designed with a magnetic seismic mass moving inside an electromagnetic coil, so that by design there are are costly and sensitive to transverse chocs.

GradeSens has integrated a state-of-the-art MEMS sensor with a built-in analogue and digital interface. This design ensures the highest quality of measurement at low frequency. Our experience on the field has demonstrated our capability to measure vibrations easily below 0.1Hz. By design, MEMS sensors measure the absolute vibration so that they can also be installed on rotating parts of your machines. The resulting data can be processed to detect irregular rotations, bent shafts, abnormal vibrations,...